The way they make microphones now, they don’t have to be this big, but, man, they sure don’t look this cool anymore.

More welds

I know, this is boring, but it’s what I’ve been doing! Can’t be helped. These look nice, right? This is what they should ALWAYS look like! Actually, the bead should be wider, but whatever. Point is they are clean and shiny looking, not rusty and full of holes. Problem is, at some point I’ll go to do this again, and for no reason that’s apparent to me, I’ll end up with rust-looking rows of pitted metal. *sigh* Someday I’ll figure this out. I just have to keep trying.

March Madness

My city hosted the final four this year. I was playing a gig downtown on Saturday night of the big weekend just blocks from the arena. The gig started at 11pm, but parking and traffic was such a mess that it was strongly recommended that I go down there at 3:30 in the afternoon(!!!) simply to unload my gear! You can’t tell so much in this photo, but it was indeed pretty crazy. There were people everywhere (peek into the right and left corners of the photo), and traffic was kind of nuts. It was kind of cool, kind of “ugh.” I did get my stuff unloaded, though the whole thing was a little dicey. I basically called the bar from my cell and said, “I’m at the light right now in front of your bar. All the parking is blocked off, and I need to get my crap loaded in. Help!” They had someone open a side door for me, and I put my hazards on, literally ran into the bar (as well as you can run through drunken knots of people with fifty pounds of equipment), worried the entire time that they were already ticketing and towing my vehicle (it was said that the city was mercilessly towing everyone), threw my stuff on stage, and then ran back out to the car, jumped in, and sped off. It felt like a bank heist! I escaped with my own vehicle! Woohoo!

The Good, and the Ugly Bad

I’ve been having issues lately with inconsistency in my welds. Things go very right, and then go oh so very wrong. Here’s an unfortunate example. These two sets of tests were done minutes apart, with no changes on my part, or none that I could perceive. Not sure what I’m doing wrong here. It’s very frustrating. I’m emailing people, asking at online forums. I’m working on it. Hopefully I’ll figure it all out before I decide to set the whole thing out in the driveway and back over it repeatedly. I kid – sort of.

On the up side, and totally unrelated to welding, I realized the other day that if you go to Google and type in rollingballsculpture like that – as all one word – my blog is the second search result, which is kind of cool.

Colors, colors, colors

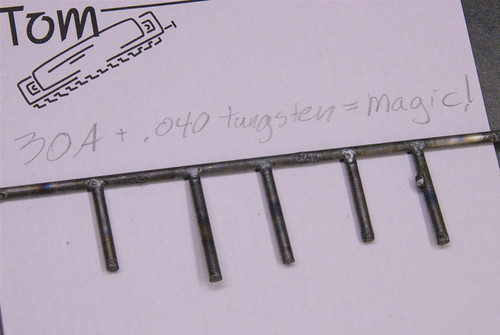

YESSSSS!!!!! Victory!!!!!

Got it!!! I know this doesn’t look like much. It looks like some grubby little gray sticks, but I assure you that this is some of the most gorgeous crap I have turned out in weeks! It’s not perfect, but, man, it’s MUCH better than it has been for months! And, really, the thing is, although I have made some good welds previously, this time I was able to repeat the process seven times! THAT is progress! And…AND!!! – when I grabbed them and wiggled them in all kinds of directions, and nothing broke off!!! SOLID!!! That is what we want!!!!

That stuff written above the practice piece are the settings on the welder for the amperage and the size of the tungsten electrode that I used to make these welds. I thought I’d never forget it, wouldn’t need to write it down, but then it occurred to me that weeks ago I’d done some welds that looked just as good as these, but hadn’t written anything down, and then I spent weeks trying to get back to this, so, can’t hurt, right?

Anyway, I could bore you with a long story about how I figured all this out, but let’s just say I practice, and practiced, and practiced, and practiced, and in between I asked for a lot of help and did a bunch of research. Now, finally(!!) I can do some solid work of which I will be proud, and which I can use to make decent sculpture. This type of welding right here is the basis upon which all my work is done, so having achieved this I have an excellent starting point from which to grow.

In short, this is really awesome. Really, really, really awesome!!!! Woot, says I.

Pedal to the metal

Here’s some more practice work from the welding bench. I just stuck a bunch of rods together, because I am still having massive trouble getting things to stick without either making cold, weak welds, or blowing obnoxiously big craters in things and overheating them. These welds are largely of the latter type. As evidence of just how crappy they are, you’ll note that there are several spots along the longest wires where it looks like there are missing “teeth.” Those places used to have short wires welded to them, but the minute I put pressure on them with my hands, they broke off. Doh.

This is not what we want, kids. This is not good. This does not make me the happiest guy on earth. However, it is all part of the learning process, and sooner or later I’ll figure this out.

Oh, and the wires are sitting on top of my brand new foot pedal control (you can switch the welder on and off with it instead of using what is, to me, a clumsy hand control). The pedal helped me get the welds started more easily, but I’m still melting everything like I have a Death Ray instead of fusing things nicely together.

More practice to come. I’ll get the hang of this yet.

Palm heart

I was over at my sister’s and she showed me this “heart” woven from a palm frond. Her friend at church made it. It is apparently a Philippine practice, where my sister’s friend hails from. When used rather than displayed, the hearts are filled with rice and other food, cooked, and then the palm is peeled away and the food inside is eaten. If you know any more about this, I’d like to hear it. I thought the whole thing was pretty cool. My sister had it displayed with her statue of Mary, as it reminded her of the Sacred Heart.

…My intentions…ooh, weird…

Following yesterday’s questioning of my sanity, this is the part where I go, “Oh yeah – THIS is why I like to do this!”

It was quite a process to get everything lined up and ready to weld, and then the welding itself, well, that’s still a struggle, but I believe I got things going well enough to keep all of this together for at least 24 hours, if not longer! This shot is from below, looking up at the piece. You can see the nifty bracket, right? Behold the niftiness! (Niftiness?? Niftyness…niff-tee-niss…)

Here’s an above shot.

Side view.

And that is our outstandingness for the weekend! Lots of work, lots of crappy welds, lots of frowning and sweating and whatever, but it’s all together! It even sort of works when you roll marbles down it. Who woulda thought??

(Bits of) my creation

Remember that little bracket from a few days ago? Back on the 21st? Well, it was lame, and something had to be done about that. Sure, it would have worked as a plain, flat piece of metal, something you could easily forget, never notice – but what in heaven’s name would be the point in THAT??! I had to throw a little wackiness at it, make it interesting, and after some work with a jig saw, drill, and grinder, we have the magic you see above. Fun, eh? It took a long time, but I think it was worth it. I’d love to create more stuff in this style. I *really* dig it. It reminds me of old Buck Rogers stuff, that fabulous 50s jet-age sort of feel that comic books and advertisements had. I hope more of this shows up here.

If you’re building one of these things, once you’ve spent way too many hours making fancy little brackets just so they’ll look like fancy little brackets, you finally get to the part where you have to actually, you know, install it. This is where multiple clamps come in handy. Not the steel blocks and clamp supporting the section of 2×4, the two welding clamps at the top of said 2×4 which are delicately balancing the platform to be welded to the sculpture, and the red-handled clips with the pipe that are holding up a long arm of the ball track (not to mention the other steel block that’s holding the lower clamp). These are probably the times where I most often go, “Why do I want to do this again?”

The answer to that question is right around the corner.