Here you can see the roll out, the exit for the sculpture. It turned out nicely, but there was plenty of tweaking involved in the area immediately below the final spiral. I spent a good long time getting that to work properly. This was another one of those details that ended up absorbing far more hours than you’d think it would or should. This is exactly the sort of thing that keeps people from building these doohickeys. It’s the little stuff that’s most challenging for the simple fact that it’s nit-picky and slow. Fortunately, I thrive on that sort of attention to detail. The real challenge for me is to be okay with it not being 100% perfect, something which no human is capable of, but which I, for some reason, think I should be able to do. This thing is working well, and I’m going to be happy with that. Onward! Completion awaits!

Tag Archives: RBS

Legs and stuff

The main part of the run is all finished. Now it’s time to put the supporting structure in place. The big looping piece that’s describing an arc and being held in place with all sorts of clippy things, that’s what I’m attaching. The lower part that shoots out of the picture will be cut short once I decide the final shape. It will probably have a slight scroll to it. I think. Maybe. Lots of times I don’t know exactly how this stuff will turn out until it’s done. You probably don’t want me building a bridge for you, at least not one that, you know, has to carry anything important. Tacoma Narrows, here I come!

Roll on, roll on!

I’m still at work on this one. It’s looking good so far. I have most of the run done at this point. It needs the final exit section, and then it will be time to add the supports/legs. At this point I’m kind of wondering at my wisdom in creating the run before building the support structure, but, well, there we are. It’s just going to go the way it’s going to go at this point. No turning back now!

Score again!

Just a little off the top

Okay, it wasn’t off the top, but I spent a ton of time filing the side of this bit of wire down so it will fit properly onto the edge of the spiral where it will be soldered. This is the kind of work that eats up evenings and leaves you going, “THAT? I’ve been sitting here for ninety minutes, and I did THAT?” Looks nice when it’s done, though. Rolls good too!

Pieces, pieces, pieces

Well, we can’t have that

Today’s pic o’ the day brings with it – an extra pic! Woohoo! You’re welcome.

I usually try to limit it to just one picture to force myself to learn to make decisions, but today’s post simply wasn’t going to go over so hot without having a “before” shot. And, um, actually, the “before” shot is really more of a “already started, but still ugly” shot.

Shall I explain? I shall. In the top photo in the foreground you can see what looks like a pretty ugly piece of wire. In the, um, aft-ground a wire that looks kinda shiny. That wasn’t like that minutes before I shot this. All the wires looked blackened and scarred up like the foremost one. I wish I’d thought to take a picture before I started cutting things off. Pity. At any rate, there were two main wires for the track that were haphazardly connected to each other with two U-shaped pieces. They were all horrible welds, and some of the pieces were nearly cut in half rather than being welded together. It was a mess, and I didn’t think it was even going to stick together for long.

With my recent success in welding, I decided I absolutly had to fix that aberration. I picked up the bolt cutters and proceeded to remove all manner of nastiness. Then I fabricated new pieces to go in place of the dead ones. It took a total of ten welds to get everything back together, and I’m happy to say that only two of those were less than decent. Unfortunately, you can actually see one of them here (that black dot on the connecting piece is a hole), but an 80% success rate for me is ridiculously high. In short, it was a good night, a very good night indeed. I hope this streak of goodness continues, then we’ll be able to look at photos of me building stuff instead of pictures of welded spots like these.

Did I mention I wanted a punch press yesterday? I’d like one, thanks. And the vertical mill also, still want that. A lot.

Did I also mention that I was looking up geometry on line and CAD stuff and that I looked up the course requirements for a machinist? Yep, losing my mind here, folks.

Tonight I’m also going to meet with someone from my NaNo group and we’re going to go over the edits and suggestions we had for each other after swappping novels. I do still write, you know, lest that be forgotten amidst this morasse of machinery obsessiveness.

RBS weld – finally!

Yes! At long last, a decent weld on the RBS! This single photo comprises my sum total of welding for the evening, but at least I have something nice to show for it. I butt-welded these two rods together (go ahead, laugh. “butt weld, butt weld, butt weld”) and they turned out the way I wanted them to! They’re together! They’re not all knotty and blobby and pitted! ‘Tis a Christmas miracle – or something!

Anyway, I’ve been trying to get the hang of this welding thing for quite some time, obviously, and I’ve been making mistakes right and left on the sculpture. Tonight it was a welcome moment of victory. I’d best hold on to this one. I may not have another for weeks to come. I mean, I totally hope that’s not true, but it’s possible.

On a related note, I’d like a band saw, a drill press, a punch, an arbor press, and a vertical mill. Just sayin’. I suppose I could get by without the drill press if I had the vertical mill. Don’t want to sound greedy.

YESSSSS!!!!! Victory!!!!!

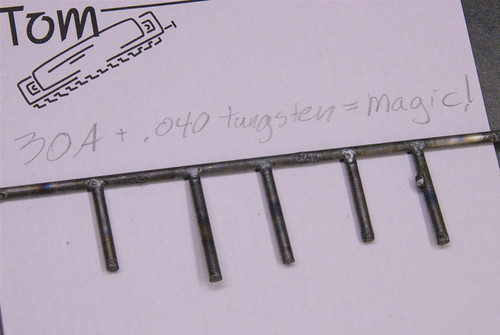

Got it!!! I know this doesn’t look like much. It looks like some grubby little gray sticks, but I assure you that this is some of the most gorgeous crap I have turned out in weeks! It’s not perfect, but, man, it’s MUCH better than it has been for months! And, really, the thing is, although I have made some good welds previously, this time I was able to repeat the process seven times! THAT is progress! And…AND!!! – when I grabbed them and wiggled them in all kinds of directions, and nothing broke off!!! SOLID!!! That is what we want!!!!

That stuff written above the practice piece are the settings on the welder for the amperage and the size of the tungsten electrode that I used to make these welds. I thought I’d never forget it, wouldn’t need to write it down, but then it occurred to me that weeks ago I’d done some welds that looked just as good as these, but hadn’t written anything down, and then I spent weeks trying to get back to this, so, can’t hurt, right?

Anyway, I could bore you with a long story about how I figured all this out, but let’s just say I practice, and practiced, and practiced, and practiced, and in between I asked for a lot of help and did a bunch of research. Now, finally(!!) I can do some solid work of which I will be proud, and which I can use to make decent sculpture. This type of welding right here is the basis upon which all my work is done, so having achieved this I have an excellent starting point from which to grow.

In short, this is really awesome. Really, really, really awesome!!!! Woot, says I.

Pedal to the metal

Here’s some more practice work from the welding bench. I just stuck a bunch of rods together, because I am still having massive trouble getting things to stick without either making cold, weak welds, or blowing obnoxiously big craters in things and overheating them. These welds are largely of the latter type. As evidence of just how crappy they are, you’ll note that there are several spots along the longest wires where it looks like there are missing “teeth.” Those places used to have short wires welded to them, but the minute I put pressure on them with my hands, they broke off. Doh.

This is not what we want, kids. This is not good. This does not make me the happiest guy on earth. However, it is all part of the learning process, and sooner or later I’ll figure this out.

Oh, and the wires are sitting on top of my brand new foot pedal control (you can switch the welder on and off with it instead of using what is, to me, a clumsy hand control). The pedal helped me get the welds started more easily, but I’m still melting everything like I have a Death Ray instead of fusing things nicely together.

More practice to come. I’ll get the hang of this yet.